Electropositive Filters

NanoCeram® is an electropositive fibrous filter media with high particle removal efficiency as well as high dirt holding capacity. When incorporated into a pleated filter, its flow rate is equivalent to, or higher than pleated filters that are rated at 1-2 microns even though NanoCeram's nominal rating is 0.2 micron. As a "broad spectrum" particle "magnet", the NanoCeram® cartridge removes both coarse and fine particulates.

Most filters separate particles by the mechanisms of sieving, inertial impaction, interception and diffusion. This is true for most membranes as well as fibrous depth filters. Electropositive filters principally use adsorption (electro-adhesion) as the filterting mechanism. Unlike Nanoceram filters, electropositive membranes have a very low dirt holding capacity and a tendency to foul quickly. They also have low reliability and high costs for materials, maintenance and actual operation.

Most filters separate particles by the mechanisms of sieving, inertial impaction, interception and diffusion. This is true for most membranes as well as fibrous depth filters. Electropositive filters principally use adsorption (electro-adhesion) as the filterting mechanism. Unlike Nanoceram filters, electropositive membranes have a very low dirt holding capacity and a tendency to foul quickly. They also have low reliability and high costs for materials, maintenance and actual operation.

Advantages

Enhanced Operations - by removing fines in addition to the coarser particulate in a water stream, many iindustries will see dramatically improved performances.

DHC - Capacity that can be hundreds of times greater than conventional filters.

• Fewer replacement elements

• Lower Maintenance costs

• Less system downtime

DHC - Capacity that can be hundreds of times greater than conventional filters.

• Fewer replacement elements

• Lower Maintenance costs

• Less system downtime

ΔP - A lower pressure drop

• Less energy consumed in forcing fluids through a "tight" filter media

• Less wear & tear on other system components

Reduced Operational Costs - no ongoing operational costs of membranes

• Capital intensive backflush systems and chemicals

• Energy consumption during backflush cycles

• Waterwaste

• Labor costs for cleaning operations

• Hazardous waste disposal from the back flushing cycles

• Less energy consumed in forcing fluids through a "tight" filter media

• Less wear & tear on other system components

Reduced Operational Costs - no ongoing operational costs of membranes

• Capital intensive backflush systems and chemicals

• Energy consumption during backflush cycles

• Waterwaste

• Labor costs for cleaning operations

• Hazardous waste disposal from the back flushing cycles

How Does Electro Adhesion Work?

The Technical Explanation:

Electroadhesion utilizes the difference in charge that may exist between a surface (or fiber) and a particle in an aqueous solution, where a charge is built up by the double layer effect. Most bacteria and most other particles are electronegative in water. Smaller particles also tend to become more electronegative. So an electropositive fixed surface would be far more effective at attracting and retaining particles than one that is electronegative.

The NanoCeram® Advantage:

The electroadsorptive ingredient in the NanoCearm® filter is a nano aluminia fiber that has a surface area from 350-500 m2/g, with virtually all of that on the outside surface of the fiber and exposed to the entire spectrum of particulate in an aqueous stream. Such high suface areas are unattainable either in a membrane or in a fibrous filter even where nanofibers are being used. Nanofibers are vey difficult to manufacture much below a 100nm diameter versus a 2nm diameter in the case of nano alumina.

And eve if a nonoaluminia fiber with a 2nm diameter were commercially available, this fiber (and virtually every other nanomaterial) would have a very strong tendency to agglomerate with the other nanofibers. Once this agglomeration occurs, the advantage of that huge surface area is lost. The key to NanoCeram's advantage is that we have developed a novel method of grafting these submicron alumina fibers permanently to a scaffold. This serves to keep the fibers separate from the one another so that each fiber can do what it is optimized to do...attract and capture submicron particles.

Electroadhesion utilizes the difference in charge that may exist between a surface (or fiber) and a particle in an aqueous solution, where a charge is built up by the double layer effect. Most bacteria and most other particles are electronegative in water. Smaller particles also tend to become more electronegative. So an electropositive fixed surface would be far more effective at attracting and retaining particles than one that is electronegative.

The NanoCeram® Advantage:

The electroadsorptive ingredient in the NanoCearm® filter is a nano aluminia fiber that has a surface area from 350-500 m2/g, with virtually all of that on the outside surface of the fiber and exposed to the entire spectrum of particulate in an aqueous stream. Such high suface areas are unattainable either in a membrane or in a fibrous filter even where nanofibers are being used. Nanofibers are vey difficult to manufacture much below a 100nm diameter versus a 2nm diameter in the case of nano alumina.

And eve if a nonoaluminia fiber with a 2nm diameter were commercially available, this fiber (and virtually every other nanomaterial) would have a very strong tendency to agglomerate with the other nanofibers. Once this agglomeration occurs, the advantage of that huge surface area is lost. The key to NanoCeram's advantage is that we have developed a novel method of grafting these submicron alumina fibers permanently to a scaffold. This serves to keep the fibers separate from the one another so that each fiber can do what it is optimized to do...attract and capture submicron particles.

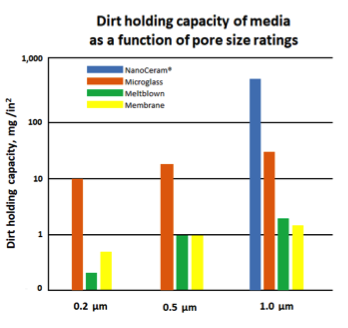

Dirt Holding Capacity

Dirt holding capcity (DHC) generally refers to the capacity of a filter cartridge to retain a given weight of particles before the cartridge plugs. Logic dictates that for a given pore size, the larger particle challenging that filter, the greater the DHC. Smaller particles would simply pass through the larger pores.

Much like a standard filter, the NanoCeram® electropositive fibrous media sieves particles larger than its average pore size. However, the NanoCeram® filter also adsorbs smaller particles resulting in DHC levels many times greater than standard filter cartridges.

In many applications, removing sub-micron particles is vital. They are responsible for much of the fouling of reverse osmosis (RO) membranes and would degrade the efficiency of ultraviolet (UV) and ozone disinfeciton systems. Membranes are surface filters with very little DHC and while their efficiency might be high, their capacity for holding dirt will often lead to premature fouling resulting in frequent cleaning cycles and increased operational costs.

Much like a standard filter, the NanoCeram® electropositive fibrous media sieves particles larger than its average pore size. However, the NanoCeram® filter also adsorbs smaller particles resulting in DHC levels many times greater than standard filter cartridges.

In many applications, removing sub-micron particles is vital. They are responsible for much of the fouling of reverse osmosis (RO) membranes and would degrade the efficiency of ultraviolet (UV) and ozone disinfeciton systems. Membranes are surface filters with very little DHC and while their efficiency might be high, their capacity for holding dirt will often lead to premature fouling resulting in frequent cleaning cycles and increased operational costs.

How long will my NanoCeram cartridge last?

Several factors can affect the life of your cartridge, bu the overriding factor is the load and type of particulate being filtered. New US EPA regulations require that the turbidity (defined as a cloudy condition in water due to suspended silt or organic matter) of municiple water must be reduced to less than 1 NTU (Nephelometric Turbidity Units).

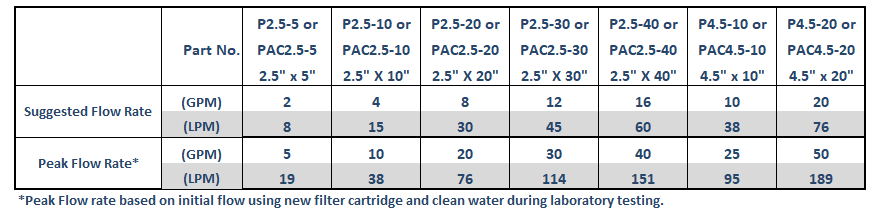

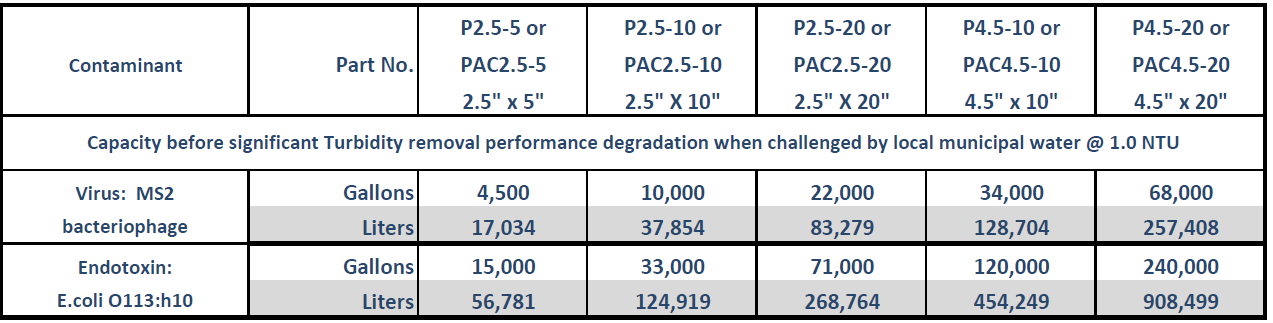

Filter Life in Municipally-Treated Water for NanoCeram® & NanoCeram® PAC Filter Cartridges (estimated)

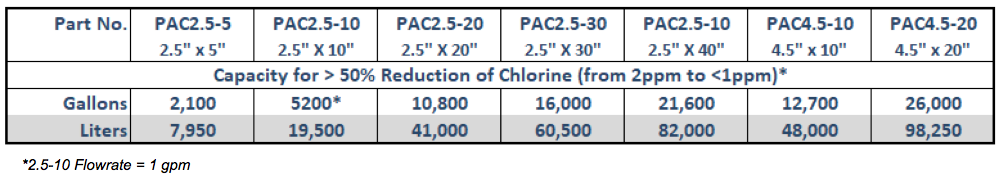

When discussing soluble contaminants such as chlorine, the flow velocity is a very important metric. All carbon-based products require "residence time" for contact between the contaminant and the carbon itself. The longer the contact time, the greater the dynamic adsorption rate of the carbon for soluble contaminants. This is where NanoCeram® PAC offers such an advantage.

Chlorine Reduction Capacity of NanoCeram® PAC Filter Cartridges (estimated)

What is NanoCeram PAC?

NanoCeram PAC represents a paradigm shift in carbon filtration in that fine activated carbon powder can now be utilized in filter media as it is held within the structure by electroadhesive forces, without using adhesives or straches that would blind or possibly deactivate the carbon. PAC offers a much greater external surface area, resulting in much more rapid adsorption of soluable contaminants.

NanoCeram P & PAC series filters reduce or remove bacteria, virus and cysts. Additionally, PAC reduces chlorine, iodine and soluble organics that may be highly toxic or may cause unpalatable taste and odor. The PAC filter is best used in those applications where a combination of fouling-resistant soluble contaminant removal and particulate reduction is desired.

For drinking water applications, the entire Argonide line of standard-sized NanoCeram and NanoCeram PAC filter cartridges have been certified to the NSF/ANSI Std. 53 for material safety only. Additional testing by the International Association of Plumbers and Mechanical Officials (IAPMO) has determined that these filter cartridges reduced cysts by at least 99.98%

NanoCeram P & PAC series filters reduce or remove bacteria, virus and cysts. Additionally, PAC reduces chlorine, iodine and soluble organics that may be highly toxic or may cause unpalatable taste and odor. The PAC filter is best used in those applications where a combination of fouling-resistant soluble contaminant removal and particulate reduction is desired.

For drinking water applications, the entire Argonide line of standard-sized NanoCeram and NanoCeram PAC filter cartridges have been certified to the NSF/ANSI Std. 53 for material safety only. Additional testing by the International Association of Plumbers and Mechanical Officials (IAPMO) has determined that these filter cartridges reduced cysts by at least 99.98%